Install Guide - Oil Stop + Chemical Resistant + Clear Top Coat (201 / 2 / 15)

This guide provides field-proven steps for installing a system that uses Epoxy.com Product 201 Oil Stop Primer on oil-saturated concrete, followed by Product 2 chemical resistant epoxy, and finished with Product 15 clear top coat. Always read and follow the latest data sheets for each product.

1 - System Overview

- Product 201 - Oil Stop Primer for oil contaminated or saturated concrete.

- Product 2 - Chemical resistant epoxy coating for industrial floors.

- Product 15 - Clear epoxy sealer / top coat for protection and gloss finish.

2 - Materials and Tools

- Materials: Products 201, 2, and 15; optional quartz aggregate if broadcasting.

- Mixing: low speed drill, mixing paddle, clean pails, calibrated measuring containers.

- Application: squeegee, notched trowel, rollers, spiked shoes, solvent for cleanup (MEK or acetone as allowed).

- Safety: gloves, eye protection, respirator, and proper ventilation per SDS.

3 - Surface Preparation

- Ensure concrete is clean, sound, and dry. Remove oil, grease, coatings, laitance, and dust.

- Shotblast or grind to the appropriate CSP profile.

- Oil-saturated slabs: degrease, rinse, and dry. Apply Product 201 to seal remaining oil.

- Concrete age: minimum 28 days or fully cured. Maintain substrate temperature above 55 deg F.

4 - Mixing Ratios (by volume)

- 201: 1 part A : 1 part B. Mix 3 minutes at low speed. Do not aerate.

- 2: 2 parts A : 1 part B. Mix 3 minutes at low speed.

- 15: 2 parts A : 1 part B. Mix 3 minutes at low speed. Components should be 65 deg F or above.

5 - Application Steps

Step 1 - Prime with Product 201 (Oil Stop Primer)

- Apply evenly to prepared, dry concrete. Work into the surface; avoid puddles.

- Allow to cure per Product 201 data sheet before applying subsequent layers.

Step 2 - Base Coat with Product 2

- Apply Product 2 at the specified spread rate for proper film build and coverage.

- For quartz systems, broadcast aggregate to rejection. After cure, sweep and vacuum excess quartz.

- Observe recoat window per Product 2 data sheet before sealing.

Step 3 - Clear Top Coat with Product 15

- Apply Product 15 as a clear sealer over the base coat or broadcast surface.

- Typical film thickness: 10???14 mil per coat. Apply one or more coats as required.

- Follow Product 15 recoat limits and curing schedule for optimal clarity.

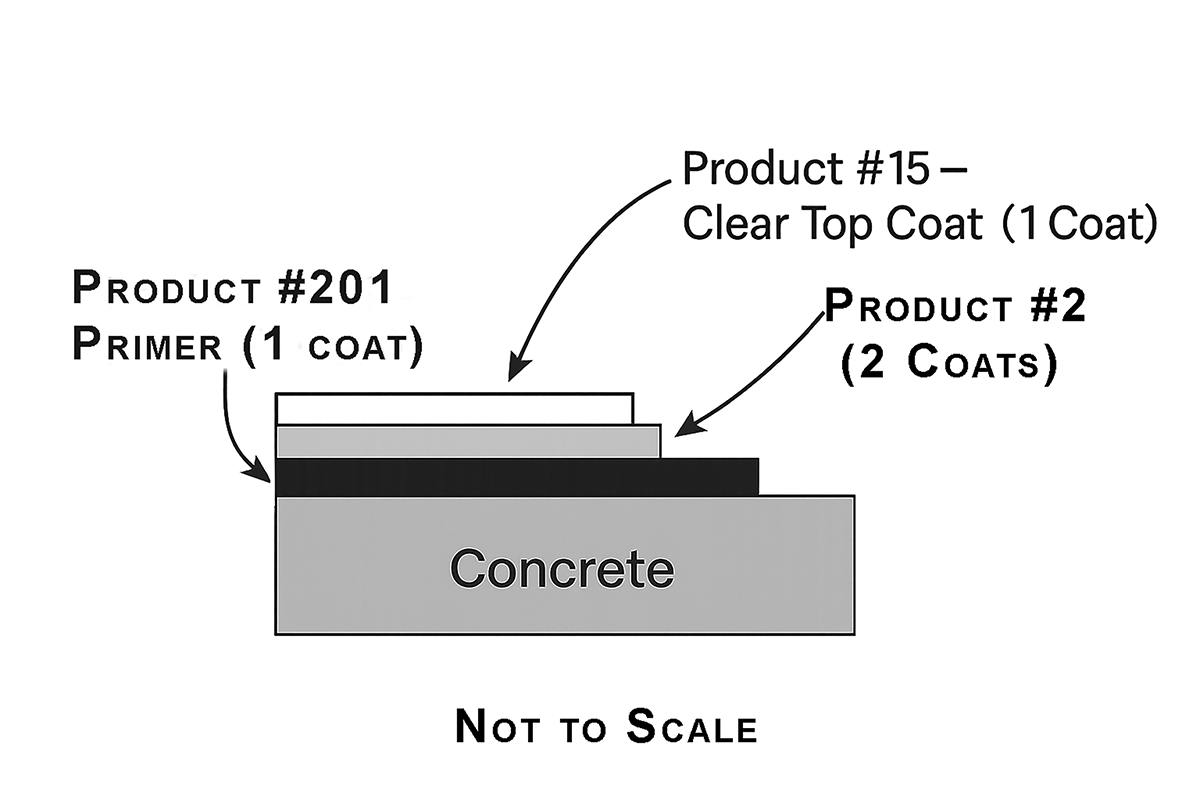

Illustration of epoxy system layers: Oil Stop Primer (201), Chemical Resistant Base (2), and Clear Top Coat (15).

Illustration of epoxy system layers: Oil Stop Primer (201), Chemical Resistant Base (2), and Clear Top Coat (15).

6 - Curing and Return to Service

- At 77 deg F: walk-on after 24 hours; light traffic after 48 hours; full cure in 7 days.

- Lower temperatures extend cure times; higher temperatures shorten pot life.

7 - Limitations

- Do not thin with solvents.

- Maintain required ambient and substrate temperatures during application.

- Do not apply over active moisture or oil intrusion.

8 - Safety and Cleanup

- Use gloves, eye protection, and ventilation. Refer to product SDS for full safety data.

- Clean tools before gel using MEK or acetone per local regulations.

References

Note: This installation guide is a convenience summary. Always follow the most current Epoxy.com product data sheets and technical bulletins for exact mix ratios, coverage rates, and cure schedules.

|

|

Proper mixing and installation is critical to the optimal success of all products.

See

Installation Tips,

Techdata, &

MSDS for more details on our products.

Be sure to contact us with any questions and/or concerns that you have.

For more information please contact:

Epoxy.com

A Division of Epoxy Systems, Inc

A Vermont Corporation

USA

We have products that have passed the test of time as well as the best new Systems available today.

Since 1980 - 40 years of the highest quality products

Hours: 9AM-4PM Eastern Time (6AM-1PM Pacific Time)

Closed for lunch from 12Noon to 1PM

321-206-1833 Customer Service - Ordering and Order Status

Katey Lambert-Fontaine, VP - Chief Operations Officer

sales@epoxy.com

Technical Support

352-533-2167 Norm Lambert, President - Technical Support Director

info@epoxy.com

352-489-1666 Accounting and Administration

Debby Lambert, CEO, and CFO

Copyright © 1994-2025 (providing

online information about the right product for the right job for nearly 30 years) EPOXY.COM a

division of Epoxy Systems, Inc. -

Florida and Vermont. All rights reserved.

|

We accept MasterCard, Visa, American Express, Discover, or Wire Transfers.

|

|